Over 400 million tonnes of paper are produced every year. From the paper mill to the printer/converter a paper roll or pallet is handled 10-20 times, and each time there is a risk of accident and/or damage. this best practice guide is dedicated to assisting every organisation and individual involved in this process in identifying and minimising these risks. in addition to addressing essential health and safety issues, the benefit is a reduction in economic and environmental degradation across the entire papermaking value chain. the guide covers paper and board in rolls and sheets used for publishing and packaging applications for major printing processes.

Collaborative working

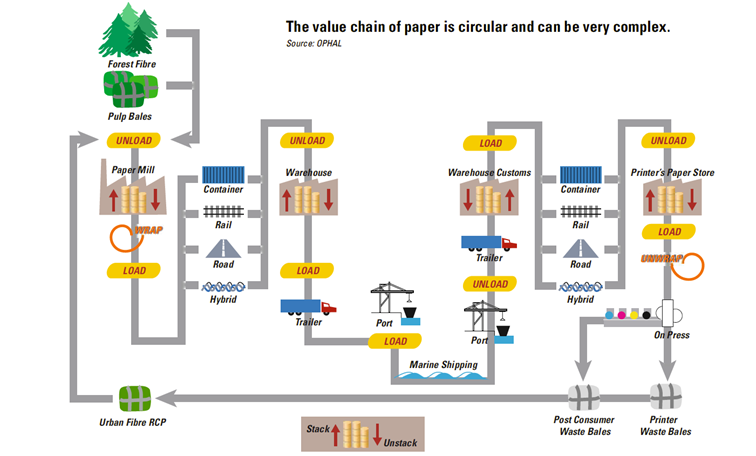

This is a unique cross-industry collaborative project that brings together expertise from across the entire paper supply chain from the mill, through transport, storage, and handling, to converting and printing. this guide offers a comprehensive view across a value chain that is both complex and global: which no single company, organisation, or region can adequately address. its goal is to provide an efficiency-building best practice tool and global reference for suppliers, transporters, converters and printers.

the project was initiated by the international Centre for Manufacture by Print and WAn-iFRA and developed with the support of the European Rotogravure Association, idealliance, and the nordic offset Printers Association with over 30 organisations and companies. the project team has collated, refined and structured best practices into a generic industry guide. this collective approach delivers cost effective international synergies to answer needs in both developing countries and mature markets at no cost to users.